WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

May 01, 2002· The Circulating Load: Practical Mineral Processing Plant Design by an Old-Tie Ore Dresser by Robert S. Shoemaker. Click here for the lowest .

Sampling of run-of-mine mill feed—A practical approach the successful application of this modified Gy's model to design a means of establishing the minimum sample size and the various stages of comminution required for broken ores (particularly gold ores) within a specified precision range, for mineral processing plant feed. Sampling theory

Practical Mineral Processing. Areas of Study: Mineral Processing. Qualifies for CMS. Premium Peer-Reviewed. Qualifies for Certification. This is a practical course in mineral processing, designed for engineers, technicians, operators, support staff and others working in the mineral processing industry but with no prior training in this area ...

Get this from a library! The circulating load : practical mineral processing plant design by an old-time ore dresser. [Robert S Shoemaker] Home. WorldCat Home About WorldCat Help. Search. Search ... practical mineral processing plant design by an old-time ore dresser a schema:CreativeWork ... # Ore-dressing plants--Design and construction ...

in the simulation of ore dressing plants. The simulator that we will be using has been developed so that it can provide a realistic description of the operation of any ore dressing plant. It is based on the best simulation techniques currently available and uses efficient numerical analysis procedures to

This is done for a number of reasons, specifically, to enable ore handling and concentrates to be transported easily, allow further processing to occur and to dispose of the gangue. The water extracted from the ore by dewatering is recirculated for plant operations after being sent to a water treatment plant.

Jun 08, 2017· This video is unavailable. Watch Queue Queue. Watch Queue Queue

CHAPTER 11 APPLICATIONS OF ORE MICROSCOPY IN MINERAL TECHNOLOGY 11.1 INTRODUCTION The extraction ofspecific valuable minerals from their naturally occurring ores is variously termed "ore dressing," "mineral dressing," and "mineral beneficiation." For most metalliferous ores produced by mining operations,

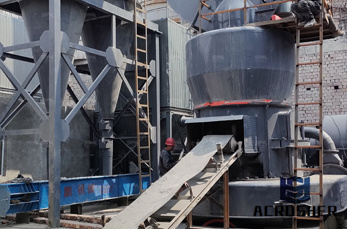

Core Competition . What you need is what we can do! In the future, Xinhai will continue to rely on three big supporting "technology, talents, management", adhere to the international development strategy, and concentrate on providing customers with modern, efficient, energy-saving mine overall construction and operational solution, to create international leading enterprises in mining industry.

Mine Design. Three parts of mine design: feasibility study, preliminary design, and construction plan. The key to mine design is all must be established on the basis of detailed investigation, and therefore Xinhai Mine Design Institute will firstly take a comprehensive field study to the mine of clients including the crude ore for dressing plant, site, water, electricity, traffic, geography, etc.

Mineral processing—sometimes called ore dressing, mineral dressing, or milling—follows mining, and it prepares the ore for extraction of the valuable metal in the case of metallic ores and produces a commercial end product from products such as iron ore and coal.

process flow for making iron ore bmaxplayhouse. High Gauss ferromagnetic iron ore wet magnetic separator Ore Dressing Production Line. High Gauss Ferromagnetic Iron Ore Wet Magnetic Separator,Hematite . different magnetic induction like forward flow, semi counter flow and counter flow. . and the CAD and CAPP of production research and process design. .

Get this from a library! Circulating Load : Practical Mineral Processing Plant Design by an Old-Time Ore Dresser.. [R S Shoemaker] -- Annotation. This how-to guide is loaded with innovative ideas and practical solutions to some of the most troublesome minerals processing challenges. From mess-free flooring to inventive crusher ...

Various Feeders Applied To Ore Dressing Plant. Feeder is machine to give materials from storage silos to give device. In beneficiation procedures, feeder determines feeding method and also the efficiency from the machine. So you should choose a appropriate feeder. You will find some common used feeders applied to beneficiation process the ...

Xinhai 4000,000 t/a Iron Ore Tailings Reprocessing Project Yunnan 4000,000 t/a iron ore dressing plant was built in 2007 and put into operation in 2008. The original processing capacity was 500,000 t/a, the annual iron concentrate was 264,300 tons, and the grade of iron concentrate was 64.00%, the recovery rate was 82.80%. September 18, 2018

Oct 27, 2011· This feature is not available right now. Please try again later.

A DESIG~~ OF AN ORE DRESSING PLANT. The ore. Tho are consIsts of ton percent zinc blond,two percent galena, one percent marcasite and eight-sevenpercent calcite.

Iron Ore Dressing Plant-Ore Beneficiation Plant-Henan Kefan, copper ore-dressing plant, Iron ore is an important iron and steel producers of raw materials, natural minerals, Ore Dressing Plant Lead & Zinc Ore Beneficiation Copper Ore Beneficiation, Iron ore dressing equipment is iron ore-dressing equipment researched and.Copper Ore Beneficiation - CrusherCopper ore dressing plant: Mining ...

ore dressing plant in pune maharashtra HST Cone Crusher HST series single cylinder cone crusher with hydraulic-driven system is a kind of new type high efficient.

Froth flotation is a process for selectively separating hydrophobic materials from hydrophilic.This is used in mineral processing, paper recycling and waste-water treatment industries. Historically this was first used in the mining industry, where it was one of the great enabling technologies of the 20th century.

The following formulas were developed during a long association not only with design and construction, but also with the operation of ore dressing plants. These formulas are here in the hope that they would prove of value to others in the ore dressing industry.

The Circulating Load: Practical Mineral Processing Plant Design by an Old-Tie Ore Dresser Paperback – May 1 2002. by Robert S. Shoemaker (Author) 1.0 out of 5 stars 1 customer review. See all 3 formats and editions Hide other formats and editions. Amazon Price New from ...

iron dressing from iron ore plant design - . design of an iron ore beneficiation plant. the grinding circuit was designed to include primary gyratory crushing, at the nurkazgan copper plant of kazachmyss, kazakhstan, two hpgr units los colorados operation iron ore .kazzinc is a major producer of copper, precious metals, zinc, and lead, with some people in mining, ore dressing, metallurgy ...

practical ore dressing plant design . practical ore dressing plant design Practical Mineral Processing Plant Design by an OldTime Ore Dresser is loaded with innovative ideas and practical . Get Price practical ore dressing plant design . Get Information; practical mineral processing plant design .