WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

the mill is used primarily to lift the load (medium and charge). Additional power is required to keep the mill rotating. 8.1.3 Power drawn by ball, semi-autogenous and autogenous mills A simplified picture of the mill load is shown in Figure 8.3 Ad this can be used to establish the essential features of a model for mill .

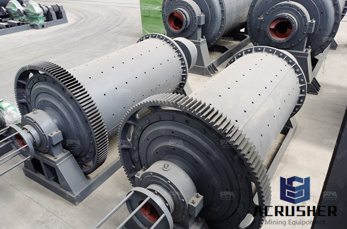

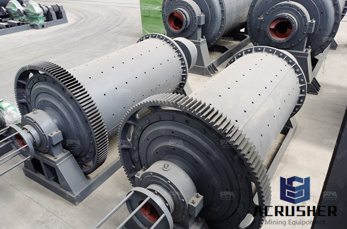

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of both ferrous and non-ferrous metals. The ball mill can grind various ores and other materials either wet or dry.

BALL MILL METHOD FOR DETERMINING THE DISINTEGRATION OF FLEXIBLE BASE MATERIAL TXDOT DESIGNATION: TEX-116-E CONSTRUCTION DIVISION 3 – 5 LAST REVIEWED: SEPTEMBER 2014 water for one hour. If 2 L (0.5 gal.) of water do not fully cover the sample, use the smallest amount of water possible to do so. Note 1—Use the dry sieve analysis as a rough check for specification .

Jun 19, 2015· The effect of Ball Mill RPM speed going from sub-critical to super-critical helps understand the Ball Mill Working Principles of ball-on-ball VS ball-on-shell grinding. The Motion of the Ball .

Mill Speed - Critical Speed. Mill Speed . No matter how large or small a mill, ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar rolling mill, its rotational speed is important to proper and efficient mill operation. Too low a speed and little energy is imparted on the product.

A ball mill can grind and homogenize small sample volumes down to the nano range. The Emax is an entirely new type of ball mill for high energy input. ... These ball mills are suitable for dry, wet and cryogenic grinding as well as for cell disruption for DNA/RNA recovery.

how can i calculate capacity of a wet ball mill. one gallon paint can ball mill; how much can we earn per day in a gold magnetic separators; how can i calculate capacity of a wet ball mill. A Series Of Unprincipled Exceptions Slate Star Codex. The more consistently one attempts to adhere to an ideology, the more one's sanity becomes a series of ...

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum 'chunk size', product size as P80 and maximum and finally the type of circuit open/closed ...

ball mill capacity wet santhosa. ATTRITORS AND BALL MILLS HOW THEY WORK, wet grind Attritors,, Ball mills are one of the more common mills and use a closed cylindrical container that is. 2009 GetsNimbler Union Process Inc. Ball mill ½ and larger, production sized units for wet milling, a pumping circula tion system augments the movement As can be seen in

Apr 27, 2019· Cylindrical energy saving grid ball mill is one of energy saving mills developed by our company, which is easy to start and saves 20-30% energy. It is lined grooved ring plate which increases the contact surface of ball and ore and strengthens the...

Ball Mill Design/Power Calculation - 911 Metallurgist. Apr 8, 2018 Ball Mill Grinding Capacity Calculator · Ball Mill Motor/Power Sizing A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material >> Get Price; How to Size a Ball Mill -Design Calculator Formula - 911 Metallurgist

how to ball mill feed capacity calculate for example · how to ball mill feed capacity calculate for example offers 2390 iso fuel tank containers products. About 20% of these are chemical storage equipment, 16% are container, and 12% are truck trailer. Get Price Alwayse Area Ball Transfer Unit Series Uk Products Spherical Roller .

Telephone:0086-371-67666660 Telephone:0086-371-67666667 Contact Person:Mr.Zhao 0086-13523465141 Fax:00086-371—68125111 Well,there is no precise calculation method that can accurately calculate the specific capacity of the cement ball mill.Here are...

Jul 22, 2019· This video is unavailable. Watch Queue Queue. Watch Queue Queue

how calculate coal crusher capacity grinding mill equipmenthow can i calculate capacity of a wet ball mill It is possible to calculate the grinding for wet grindingMore precisely Download as PDF File pdf how shall i calculate the grinding capacity of wet ball mill pdf,grinding mills volume grinding mill equipmentPerformance enhancement tools for grinding mills pdf Selecting Wet .

For overflow ball mills, the charge should not exceed 45% of the mill volume . For grate discharge mills, the charge should occupy about 50% of the mill volume . Bond developed a relationship that can be used to determine the percent charge by volume as a function of the vertical height above the charge, He, and the radius of the mill, R, i.e.,

How can I determine the best RPM for Dry Ball Milling machine in order to let the balls to fall from the best angle(s) ? ... If you can see ball motion of your ball mill. Best way to determine the ...

Ball Mill Loading - Wet Milling. Ball Mill Loading (wet milling) When charging a ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar use on a jar rolling mill it is important to have the correct amount of media and correct amount of product.

The grinding process can also take place in dry or wet conditions ... An important characteristic of an industrial ball mill is its production capacity which is measured in tons of production per hour. The production capacity depends . 53 on mill dimensions, the type of the mill .

Bond ball mill grindability test for overflow wet ball mills. An approach was proposed by Erdem (2002) for dry multi-component cement grinding ball mills, using the results of the Bond ball mill grindability test. For all model based methods, a reliable method to calculate mill power draw for a

Dec 12, 2016· If P is less than 80% passing 70 microns, power consumption will be. Ball Mill Power Calculation Example. A wet grinding ball mill in closed circuit is .

Ball mills design for grinding feldspar lumps raymond mill calculations how shall i calculate the grinding capacity of wet ball mill ball mill critical speed calculate capacity of a grinding mill crusher usa capacity calculation price of ball mill for talc posts related to ball mill capacity.

capacity and size of a ball mill Calculate Ball Mill Grinding Capacity View Larger Image; The sizing of ball mills and ball milling circuits from laboratory grinding tests is largely a question of applying empirical equations or factors based on accumulated experience.

An overfilling indicator for wet overflow discharge ball mills. ... judged by the change in hydrocyclone performance that is in closed circuit with the secondary wet grinding ball mill, the uncertainty associated with the simulated ball mill capacity renders difficulties in plant optimisation, particularly when the ball mill capacity is a major ...