WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

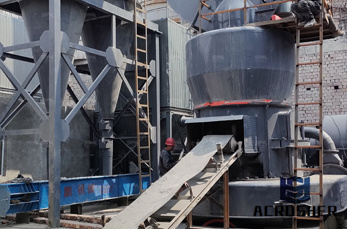

* Mill internals, media, liners and diaphragms. * Ventilation, cooling and drying. * Control concepts. * Grinding aids and other tools to boost efficiency. Module 3 – Vertical mills. This module will cover the technology of vertical mills used for raw and finish grinding in the cement manufacturing process.

Home → Products → Cement Plant Wear Parts → Vertical Roller Mill Wear Parts We offer a broad range of durable replacement parts for vertical roller mills. Replacement wear parts such as tires, grinding ring segments, armor rings and spindle shields are cast from our high chromium alloy irons and fully heat treated for optimum mechanical ...

Feb 26, 2013· This film demonstrates all aspects of the FL ATOX® raw mill: how it saves space and energy and why it has been proven to deliver reliable operation for crushing and grinding all .

This is the 3rd part in a cement plant. The process is mentioned in the enclosed movie. Here, the raw mixture is ground in a vertical mill. The gasses however .

Picture: Loesche , Germany CEMENT SikaGrind® FOR VERTICAL ROLLER MILLS. 2 CEMENT 2 SikaGrind® FOR VERTICAL ROLLER MILLS SikaGrind® ... energy of a cement plant. Vertical Roller Mills (VRM) have a clearly higher energy efficiency ... made concrete to be the most important construction material at all.

Picture: Loesche , Germany CEMENT SikaGrind® FOR VERTICAL ROLLER MILLS. 2 CEMENT 2 SikaGrind® FOR VERTICAL ROLLER MILLS SikaGrind® ... energy of a cement plant. Vertical Roller Mills (VRM) have a clearly higher energy efficiency ... made concrete to be the most important construction material at all.

Basic engineering services for the plant layout, the electric and control equipment and the civil engineering will also be in the company's scope of supply. The delivery of this grinding plant will boost the number of MPS mills sold to the Iranian cement industry to 45, 25 mills for raw material grinding and 20 for cement finish grinding.

Cement, mostly Portland Cement, is made from a mixture of calcium carbo-nate (generally in the form of lime-stone), silica, iron oxide and alumina. ... in a cement plant. Use of process analyzers in cement plants ... the raw materials, ground in the slurry mill and properly blended in water basins, are fed into the

Our best-in-class OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag. Its cutting-edge design features consistently deliver the highest quality products with the greatest efficiency. It is affordable to install and cost effective to operate over your cement plant.

300 t/d Cement Production Line 300t/d cement production line designed by Great Wall machinery, fully learns from the lessons and experiences of more than 20 years of NSP production line design, advanced vertical roller mill grinding system and DCS automatic control system.

This is a Vertical Raw Mill having a separator with 4 Nos. Cyclones with Fan. It has an Electro Static precipitator and a Fan. ... Surma Cement Plant-Raw Mill & ESP. Harvey Fonseca. March 1st, 2014 ... This is a Cement Plant in Surma-Bangladesh. It also has a Truck, driver & a man. Show more... Download files Like Share. 553 Downloads 131 Likes ...

Jiangsu Pengfei Group Co., Ltd is one of the leading Turnkey Cement Plant manufacturers, the manufacturing and exporting base for complete set of cement machinery & equipment. Our company can take on the complete set of service such as manufacturing, installation, debugging, etc for the cement machinery, metallurgy, chemical, environment protection industry.

ones replaced the gearboxes of a horizontal cement mill and a horizontal raw mill in 1993. Both new gearboxes were of CPU type. The latest installation was a WPU type gear unit for another vertical raw mill in 2005. Cementos La Cruz Azul also encountered problems with the gearbox of a Polysius roller mill type RM/46/26 for raw grind-

Feb 26, 2013· This is the ATOX movie for raw mill grinding in an animated version. ... Dangerous Biggest Crankshaft Forging Process in Metal Heavyweight Forging Factory Germany, US, China ...

uses the test-roller mill Atrol (throughput approx. 240 kg/h) for grindability testing and quantitative prediction of wear in industrial mills. Roller mill for granulated blast furnace slag grinding in China. Roller mill for cement raw material grinding in China. Roller mill for cement clinker grinding in Mexico. Coal grinding plant in Poland.

Feb 10, 2016· VRM vs Ball Mill for Cement Grinding. Good Days! Gentlemen, Anybody in this forum who have had some practical/extensive experience on Vertical Roller Mill being used for cement grinding? We are planning to put up a new cement grinding plant using Vertical Roller Mill(300-350 – TPH) and before implementing the project, we would like to

A rawmill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement.Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement mill.The rawmilling stage of the process effectively defines the chemistry (and therefore physical properties) of the finished cement, and has a large effect upon the ...

A wide variety of raw mill in cement plant options are available to you, such as free samples. There are 476 raw mill in cement plant suppliers, mainly located in Asia. The top supplying countries are China (Mainland), India, and Algeria, which supply 99%, 1%, and 1% of raw mill in cement plant respectively.

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement.Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

MVR vertical roller mill with planetary gearbox MVR vertical mill with conventional drive: economical solution for small to medium output rates For the preparation of cement raw material, cement, and granulated blast-furnace slag with small to medium output rates, the MVR mill with conventional drive is .

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant - the kiln, the cement mill etc.. For information on materials, including reactions in the kiln, see the ' Clinker ' pages.

Reliable and efficient cement production. ... Optimally equipped with our speciality lubricants 4 Lubricants for raw cement plant transport 6 Lubricants for crushing processes 8 Lubricants used in clinker production 20 ... Crusher Raw mill Raw material silo Cooler Pre-heater tower Kiln Dispatching Finishing mill

AVAILABLE AND EMERGING TECHNOLOGIES FOR REDUCING GREENHOUSE GAS EMISSIONS FROM ... bind together bricks or stones) and concrete (bulk rock-like building material made from cement, aggregate, sand, and water). By modifying the raw material mix and the temperatures utilized in ... While vertical roller mills are feasible, they have not found wide ...

Our Cement Rotary Kiln Simulator is the most effective tool to train personnel in all the aspects of the operation of a Rotary Kiln. Using laws of physics and chemistry it simulates in slightly faster than Real-Time the changing conditions of a Rotary Kiln. ... Vertical Raw Mill Overview HMI. ... Use the Cement Plant Simulator to train your ...