WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

The maximum safe operating speed of a ballscrew assembly for normal operation is 80% of the critical speed provided the ball speed limit has not been exceed. The critical speed is a function of the unsupported screw length, the screw diameter, and the end bearing supports.

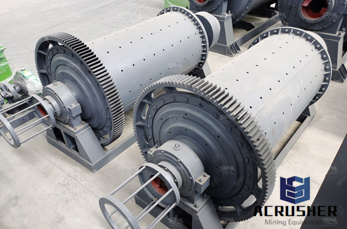

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. ... Critical speed ...

The larger the diameter, the slower the rotation. ... "Critical Speed", and ball mills usually operate at 65% to 75% of the critical speed. ... creating a cheap (under $100) ball mill. ... diameter of the motor pulley (1inch) divided by the diameter of the drum ... the formula for critical speed becomes: Chat Now. Ballscrews - Hiwin.

ball mill drum speed critical . Ball Mill Drum Speed Critical | Manganese Crusher Search ball mill drum speed critical to find your need Zenith Mining and Construction Machinery is a global . Inquiry; Ball Mill Critical Speed - Mineral Processing / Metallurgy. A Ball Mill Critical Speed (actually ball, rod, AG .

Ball Mill Critical Speed - Mineral Processing Amp . 2019-6-20 A Ball Mill Critical Speed actually ball rod AG or SAG is the speed at which the centrifugal forces equal gravitational forces at the mill shells inside surface and no balls will fall from its position onto the shell The imagery below helps explain what goes on inside a mill as speed varies Use our online formula The mill speed is ...

At what speed will the mill have to be run if the 100 mm balls are replaced by 50 mm balls, all the other conditions remaining the same? Calculations: The critical speed of ball mill is given by, where R = radius of ball mill; r = radius of ball. For R = 1000 mm and r = 50 mm, n c = 30.7 rpm. But the mill is operated at a speed of 15 rpm.

ball mill drum speed critical - sethhukamchandcoin. ball mill drum speed critical 82 Grinding glaze materials- ball mill drum speed critical,Therefore a ball mill with a steel drum can work without a lining (except for white body, where rust [Chat Online] Ball Mill Drum Speed Critical - mayukhportfoliocoin.

Critical rotation speed of dry ball-mill was studied by experiments and by numerical simulation using Discrete Element Method (DEM). The results carried out by both methods showed good agreement.

The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media. The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls.

The drive sets the grinding drum into slow rotation, whereby the bed of grinding media is activated. Ball mills are usually operated at 75% of the critical speed. If the speed is slower, the balls roll in a cascading motion, whereas at higher speeds, the balls are .

ball mill drum speed critical - nametvinum. ball mill critical speed black powder - ellul A Ball Mill Critical Speed actually ball The percent of critical speed is the ratio This video should the working principle of a ball mill and the ball. A Ball Mill is a rotating drum with dozens of lead balls inside.

Ball Mill Critical Speed - Mineral Processing Amp . 2019-6-20 A Ball Mill Critical Speed actually ball rod AG or SAG is the speed at which the centrifugal forces equal gravitational forces at the mill shells inside surface and no balls will fall from its position onto the shell The imagery below helps explain what goes on inside a mill as speed varies Use our online formula The mill speed is ...

If speed of rotation is very high, the balls cling to the drum walls due to centrifugal force. Therefore, intense grinding action is obtained only when drum rotates at critical speed and here the ball mill rotates at a speed which is neither slow nor very high.

S.O. - Super Orion Ball Mill - hosokawa-alpine The drive sets the milling drum into slow rotation and the bed of milling media is thus activated, i.e. ...Ball mills are usually operated at 75% of the critical speed.

The production rate of a ball mill process is indicated in the manufacturer's technical specifications and it is proportional to the drum rotation speed. The energy needed for the production of 1 ton of lead oxide is fairly constant when the mill operates at between 55% and 90% of its critical rotation speed.

The TM 300 Drum Mill is used for the preparation of granules and powders. The grinding process is performed either in dry or wet conditions. The drum mill can be operated either as a Ball or as a Rod Mill by using the corresponding module. A sufficient number of balls or rods is required for an effective grinding process.

A combination drum and scoop feeder can be supplied if necessary. This feeder is made of heavy steel plate and strongly welded. ... Optimum Ball Mill Speed. ... nc is the mill speed in fraction of critical speed; Li and Di are length and diameter inside shell lining respectively (in meters) For a mill with more than 2.1 m (7′) diameter the ...

Jun 19, 2015· The effect of Ball Mill RPM speed going from sub-critical to super-critical helps understand the Ball Mill Working Principles of ball-on-ball VS ball-on-shell grinding. The Motion of the Ball Charge

May 22, 2019· The ball mill consists of a metal cylinder and a ball. The working principle is that when the cylinder is rotated, the grinding body (ball) and the object ... This is the critical speed of the 180 litre wet mill currently used in cemented carbide production. ... The ratio of the volume of the ball to the volume of the drum is called the filling ...

Figures 8.5 for the popular mill types. 3 c is the mill speed measured as a fraction of the critical speed. More reliable models for the prediction of the power drawn by ball, semi-autogenous and fully autogenous mills have been developed by Morrell and by Austin. (Morrell, S. Power draw of wet tumbling mills .

TECHNICAL NOTES 8 GRINDING R. P. King. The critical speed of the mill, & c, is defined as the .Figure 8.3 Simplified calculation of the torque required to turn a mill. .To size a ball mill or rod mill .

Oct 26, 2018· Find out more about the principles of grinding in ball mills from Orbis Machinery, LLC. Call us today for more information 262-522-1939. ... Action inside a Ball Mill drum is not a haphazard process. Stirring is not random nor is the throwing of the charge. ... Faster RPM are required for smaller mills to reach critical speed.

Oct 19, 2006· What it is the optimun speed for a ball mill ? - posted in Pyrotechnics: I have done a ball mill, recenly finished, but the motor has too rpms, is too fast for use in a ball mill (the pvc cylinder that i use, left of the shafts). With the motor i will use a 40 mm pulley, because i have a 50 mm driven pulley, in one of my two shafts. In the other side of my shafts there are two 40 mm ...

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell's inside surface and no balls will fall from its position onto the shell. The imagery below helps explain what goes on inside a mill as speed varies. Use our online formula The mill speed is typically defined as the percent of the Theoretical ...